|

|

|||||||||||||||||||||||||||||||||||||||||

|

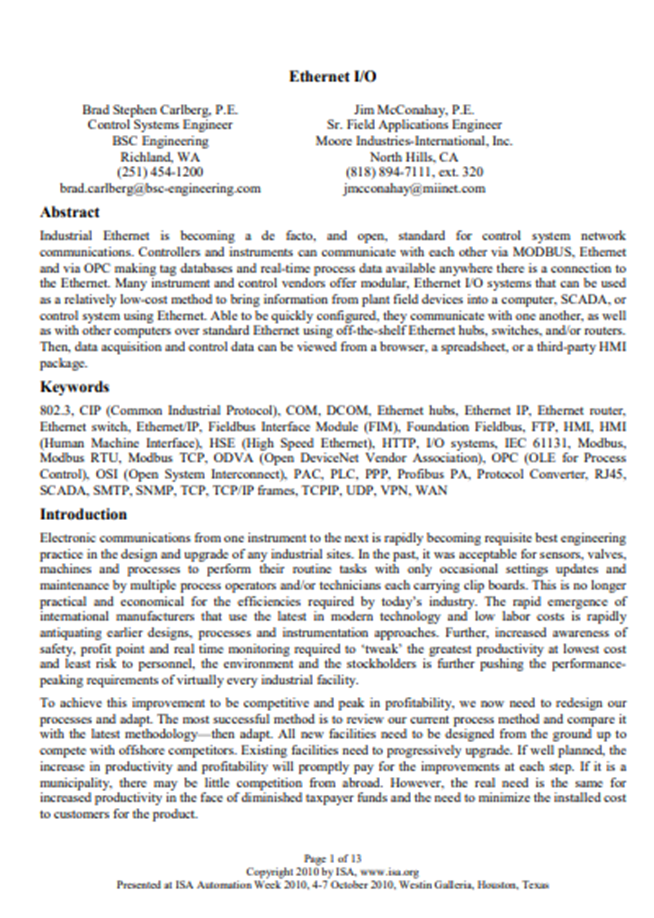

Brad Stephen Carlberg, P.E. P.O. Box 1219, Hoodsport, WA 98548 (251) 454-1200 e-mail: brad.carlberg@bsc-engineering.com Homepage: http://www.bsc-engineering.com/

|

|||||||||||||||||||||||||||||||||||||||||

|

Education |

|||||||||||||||||||||||||||||||||||||||||

|

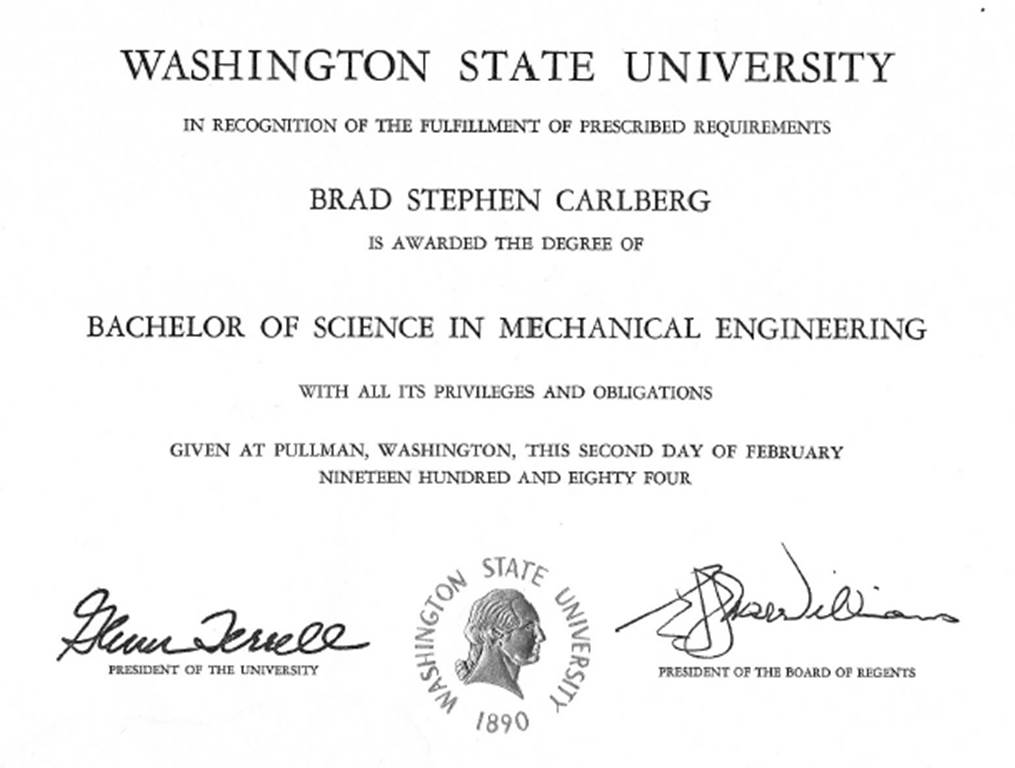

Washington State University; Pullman, Washington |

|||||||||||||||||||||||||||||||||||||||||

|

Bachelor of Science / Mechanical Engineering; February, 1984 |

|||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

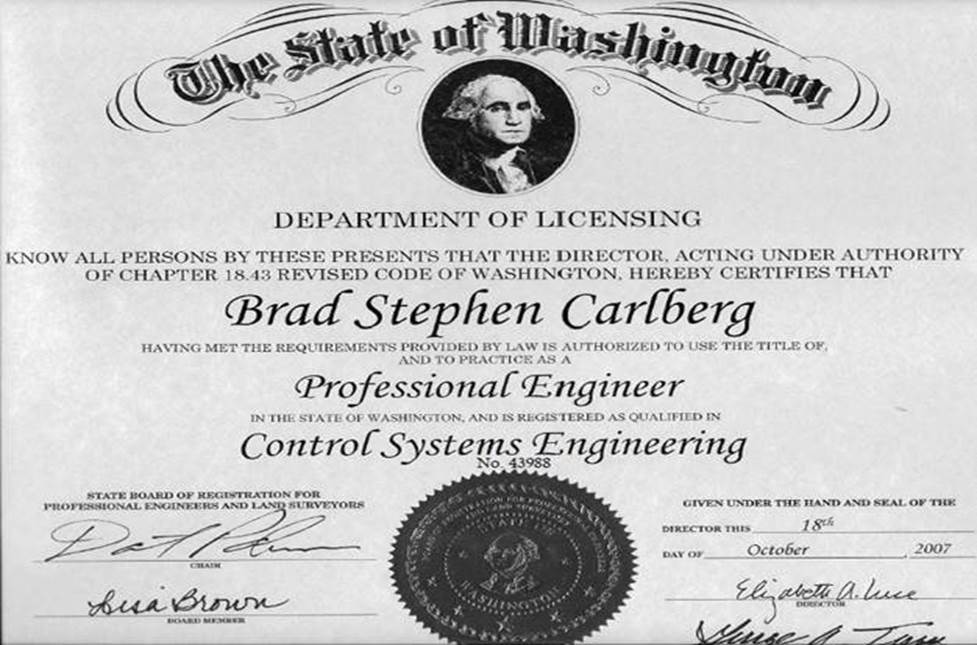

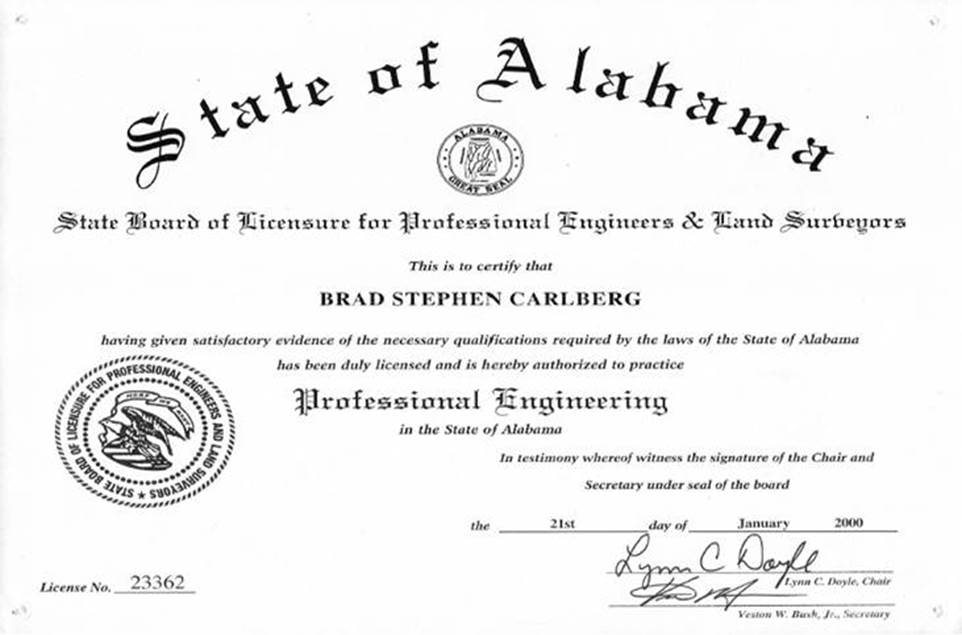

Registered Professional Control Systems Engineer |

Registered Professional Control Systems Engineer |

||||||||||||||||||||||||||||||||||||||||

|

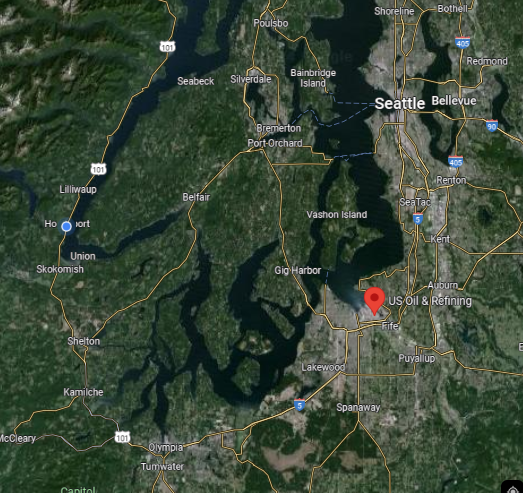

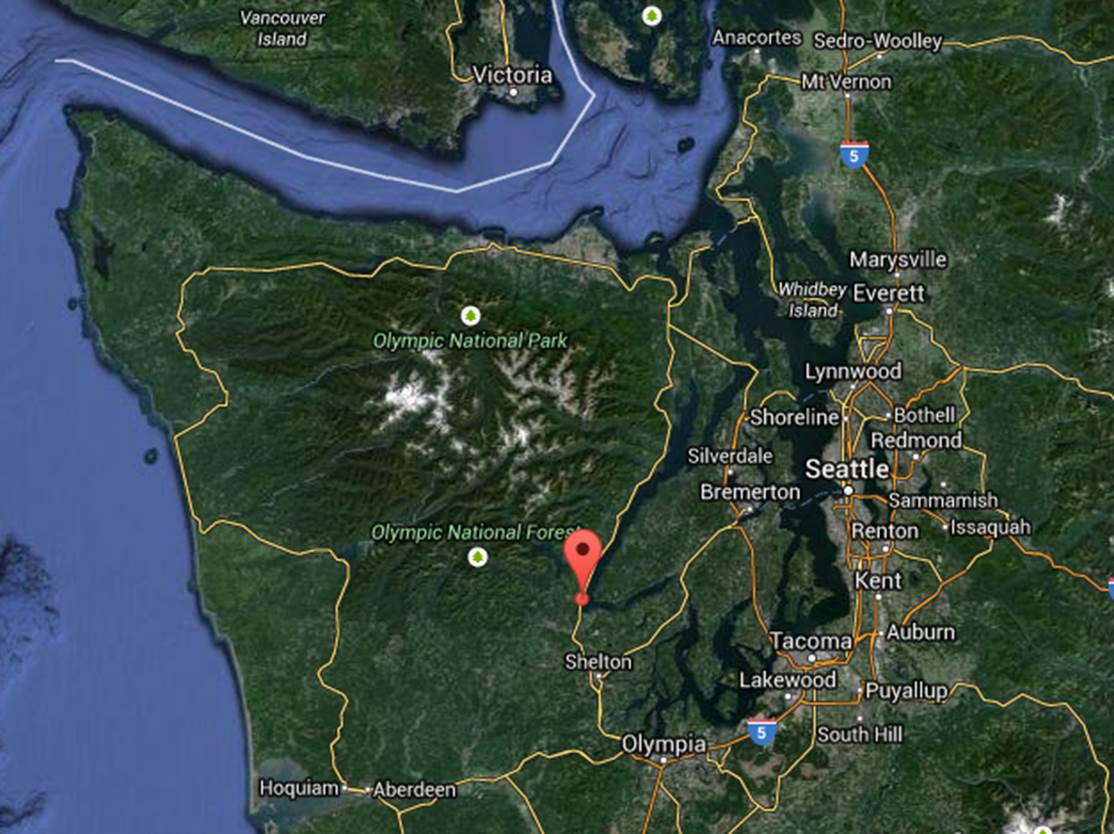

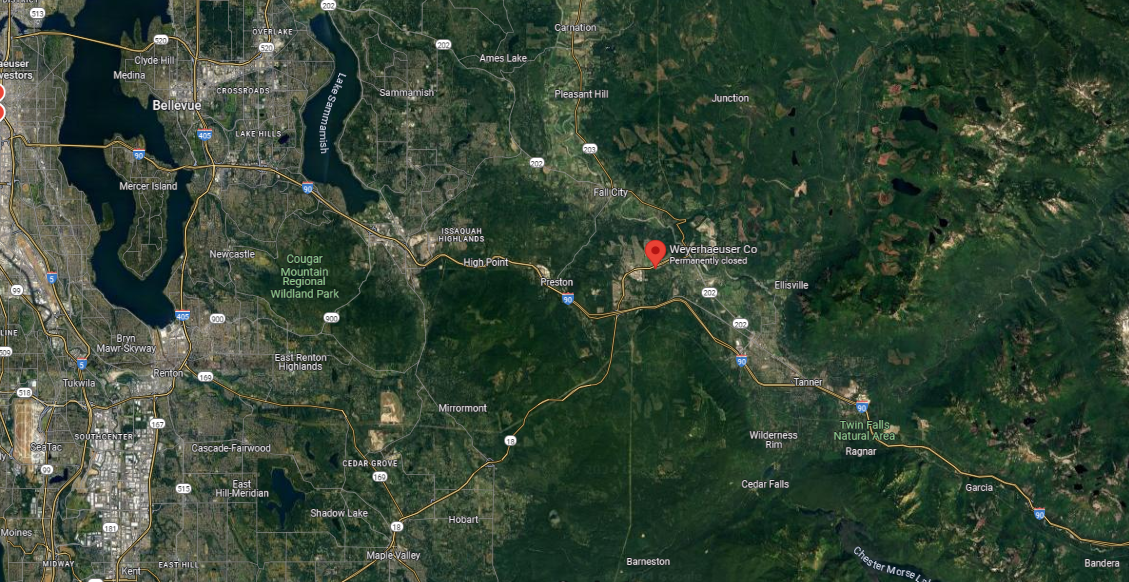

Projects Map |

|||||||||||||||||||||||||||||||||||||||||

|

1. Mason County Planning Advisory Commission Shelton, WA |

|||||||||||||||||||||||||||||||||||||||||

|

2. Potlatch Beach Mutual Water Company in Potlatch, WA |

|||||||||||||||||||||||||||||||||||||||||

|

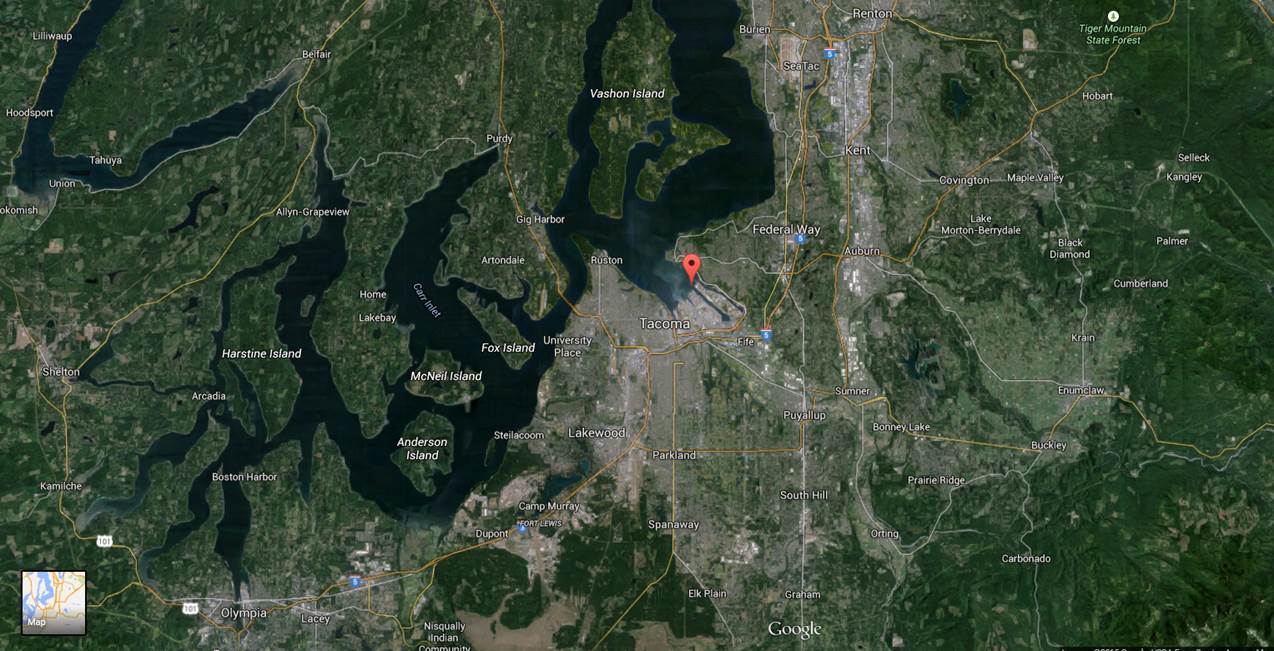

3. US Oil & Refining - Tacoma Refinery |

|||||||||||||||||||||||||||||||||||||||||

|

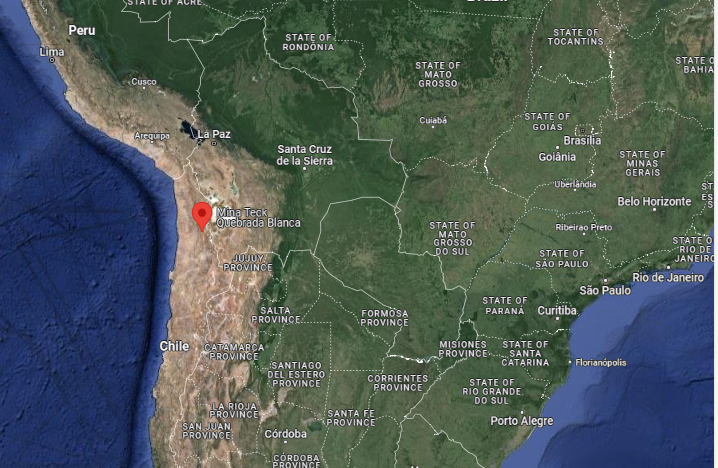

4. Quebrada Blanca Phase II Project in Iquique, Chile. |

|||||||||||||||||||||||||||||||||||||||||

|

5. Packaging Corporation of America; Wallula, WA |

|||||||||||||||||||||||||||||||||||||||||

|

6. Washington State Infragard |

|||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}7. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}United States Department of Energy (USDOE) for the Hanford Vitrification Plant Richland, WA; |

|||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}8. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Georgia-Pacific Clatskanie, OR |

|||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|||||||||||||||||||||||||||||||||||||||||

|

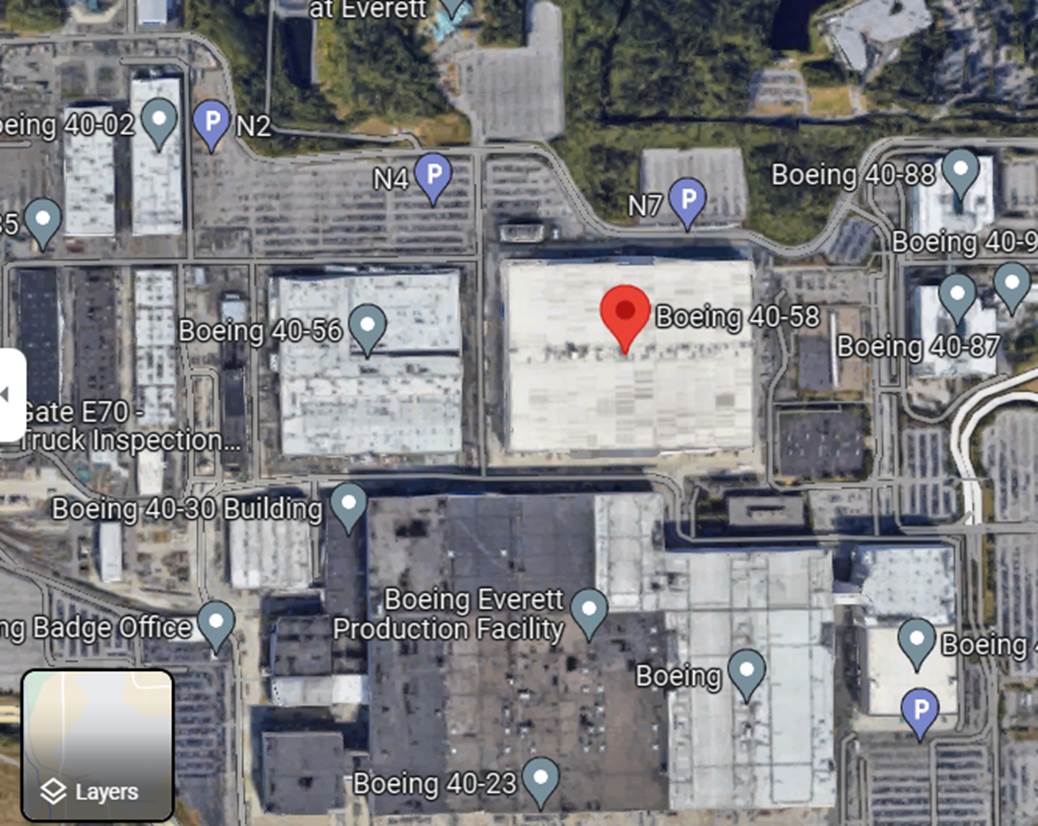

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}9. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Boeing Commercial Airplane Division; Everett, WA |

|||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|||||||||||||||||||||||||||||||||||||||||

|

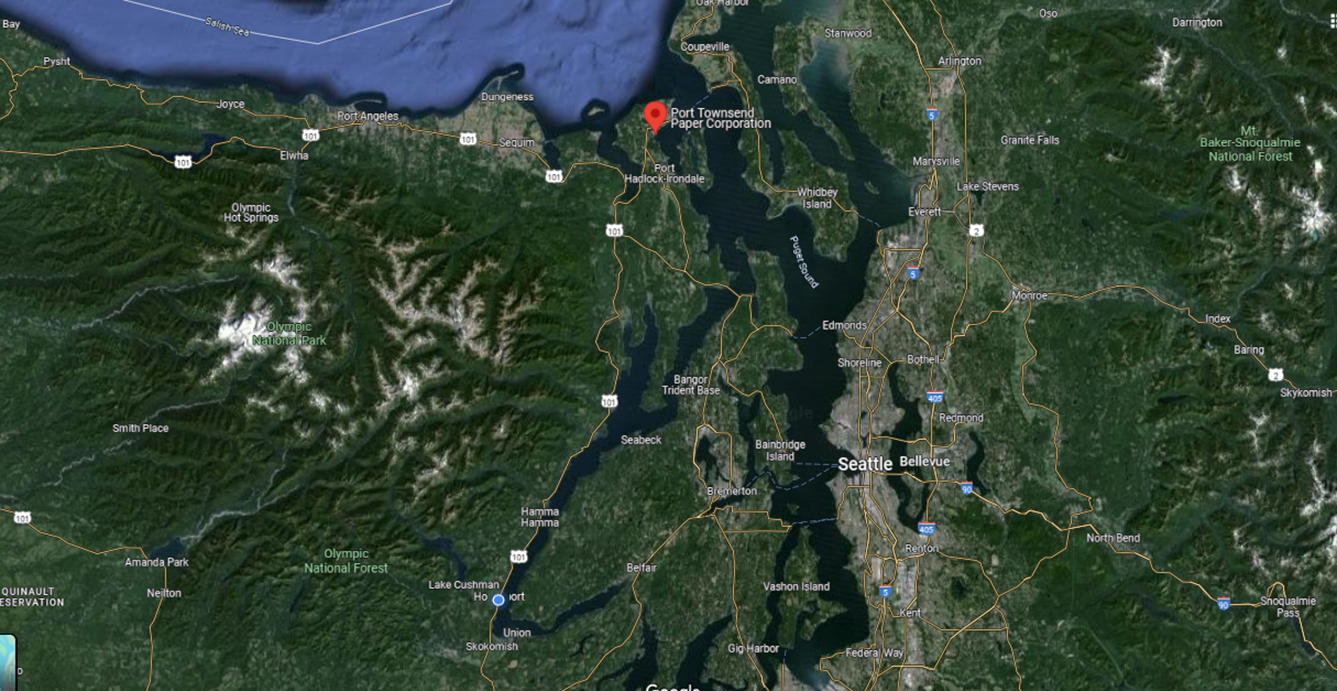

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}10. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Port Townsend Paper Corporation; Port Townsend, WA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

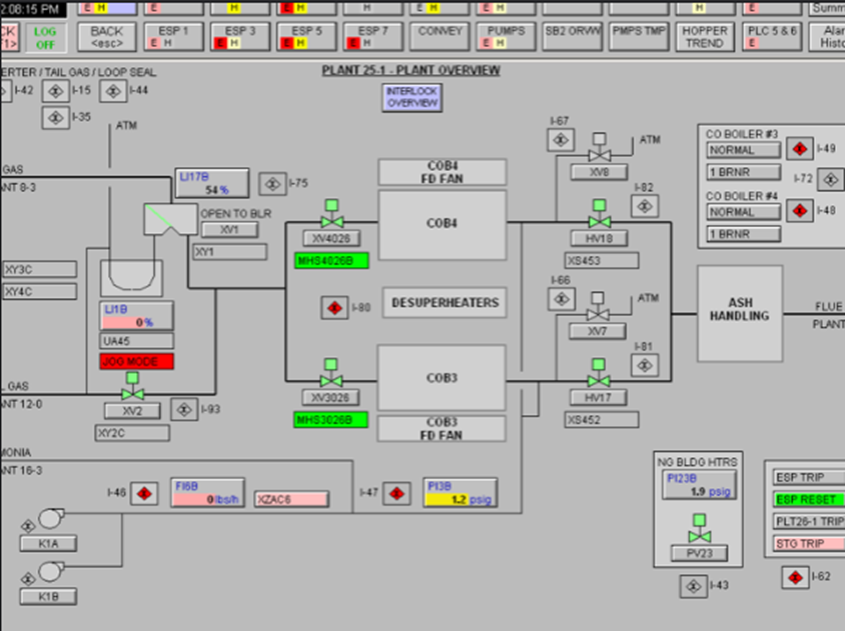

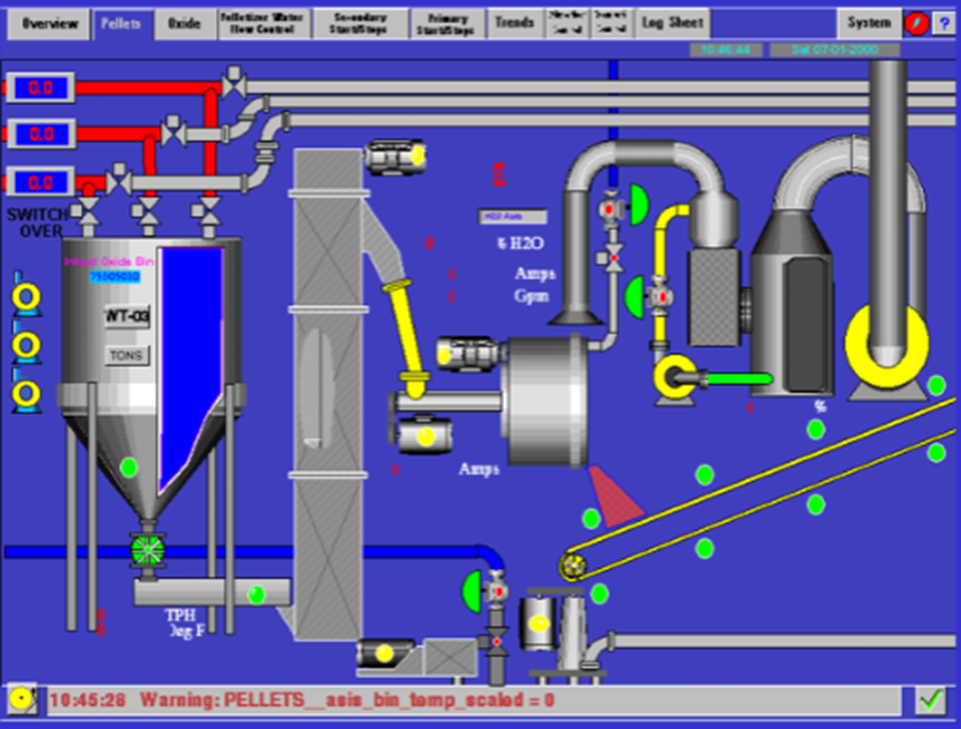

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}11. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Georgia-Pacific in Brewton, AL.b |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

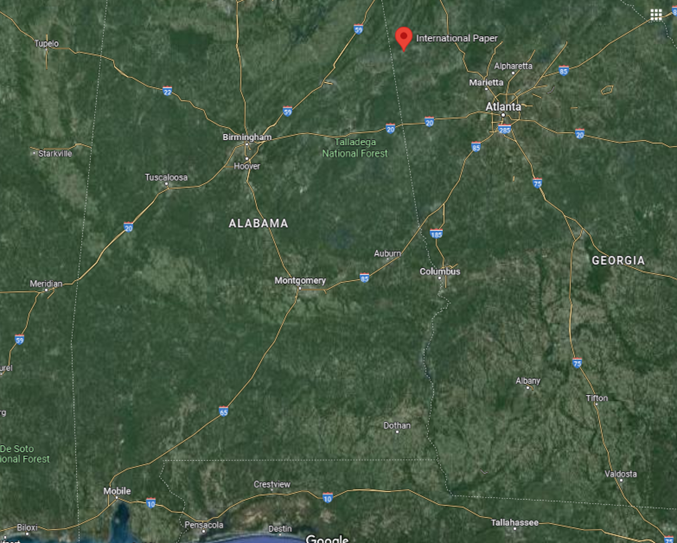

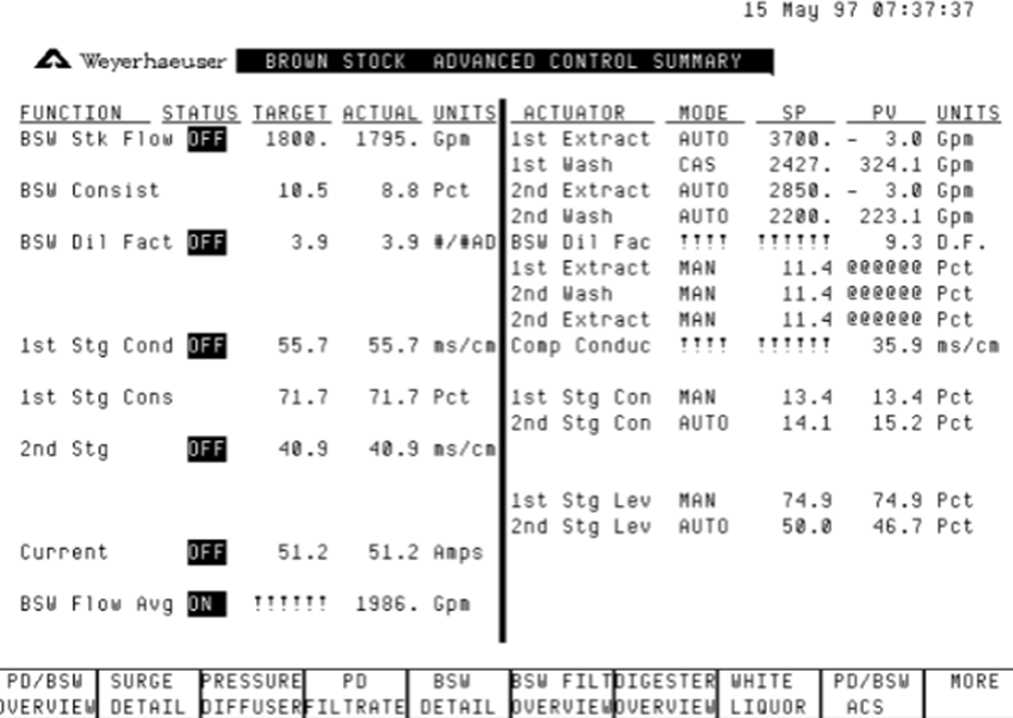

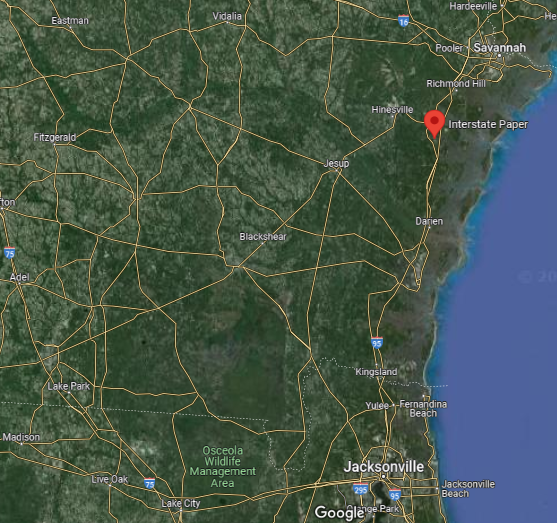

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}12. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Weyerhaeuser (now I-P) Port Wentworth, GA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

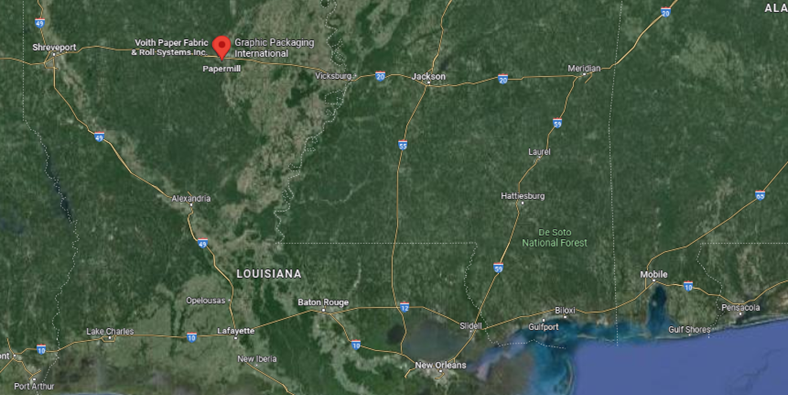

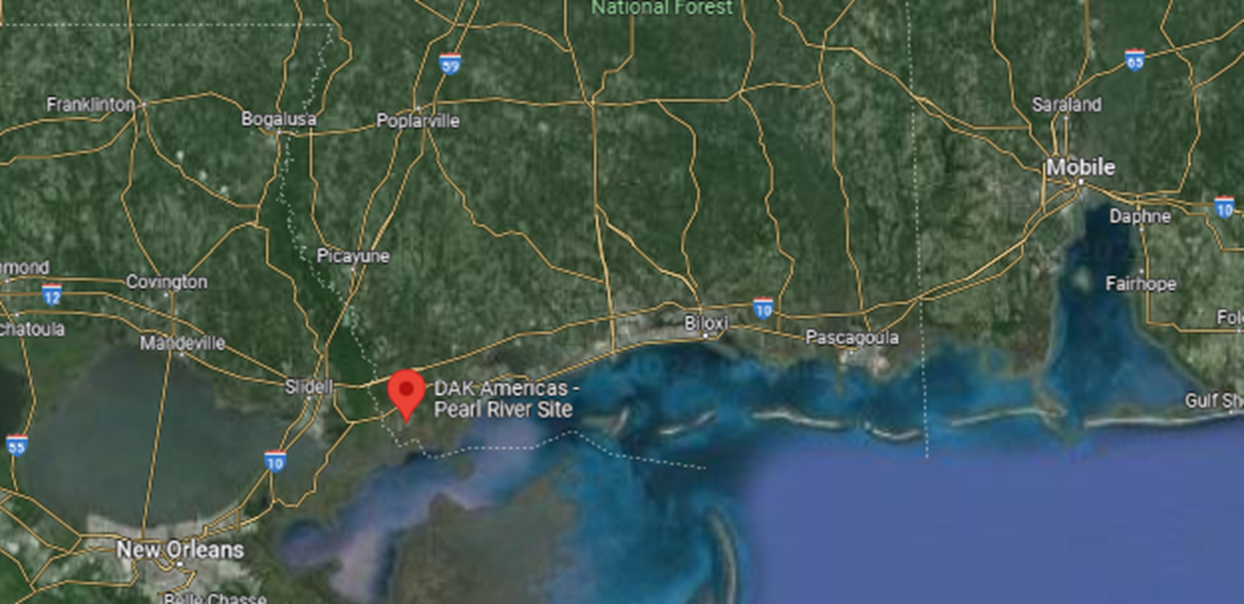

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}13. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}International Paper in Bogalusa, LA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Westinghouse Ovation DCS |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}14. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Worley Parsons & Pasadena Water & Power in Pasadena, CA for the Glenarm Repowering Project Gas Turbine, Steam Turbine, & Balance of Plant (BOP) |

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

||||||||||||||||||||||||||||||||||||||||

|

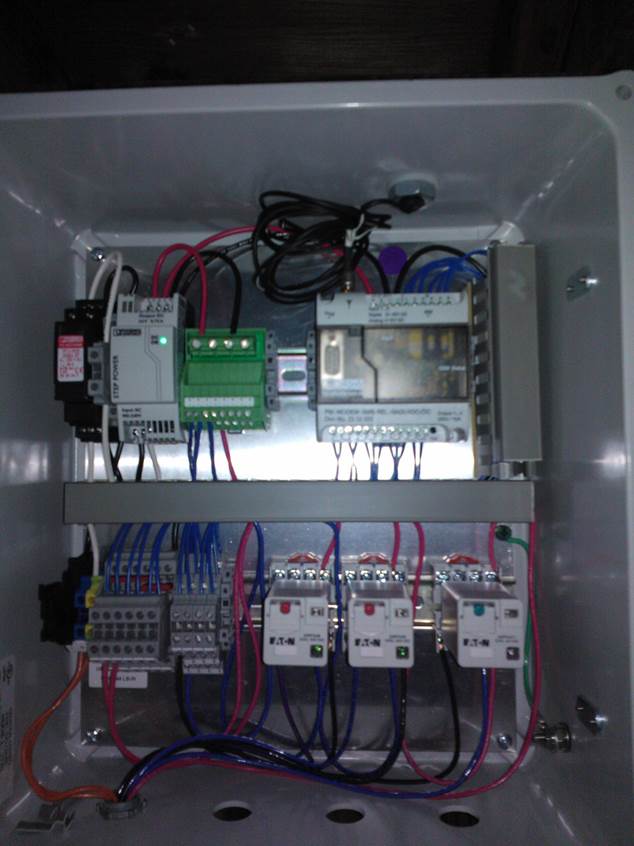

Siemens S7-1215 PLC |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}15. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Volpentest HAMMER Federal Training Center in Richland, WA |

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

||||||||||||||||||||||||||||||||||||||||

|

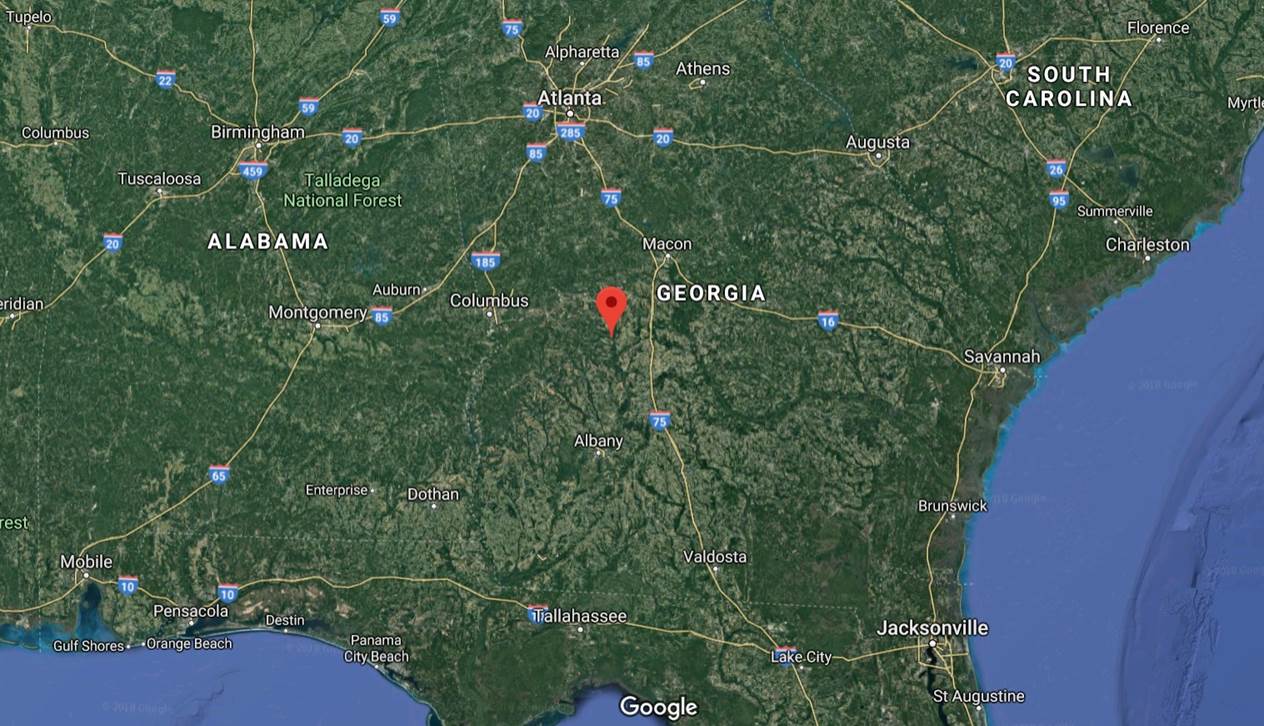

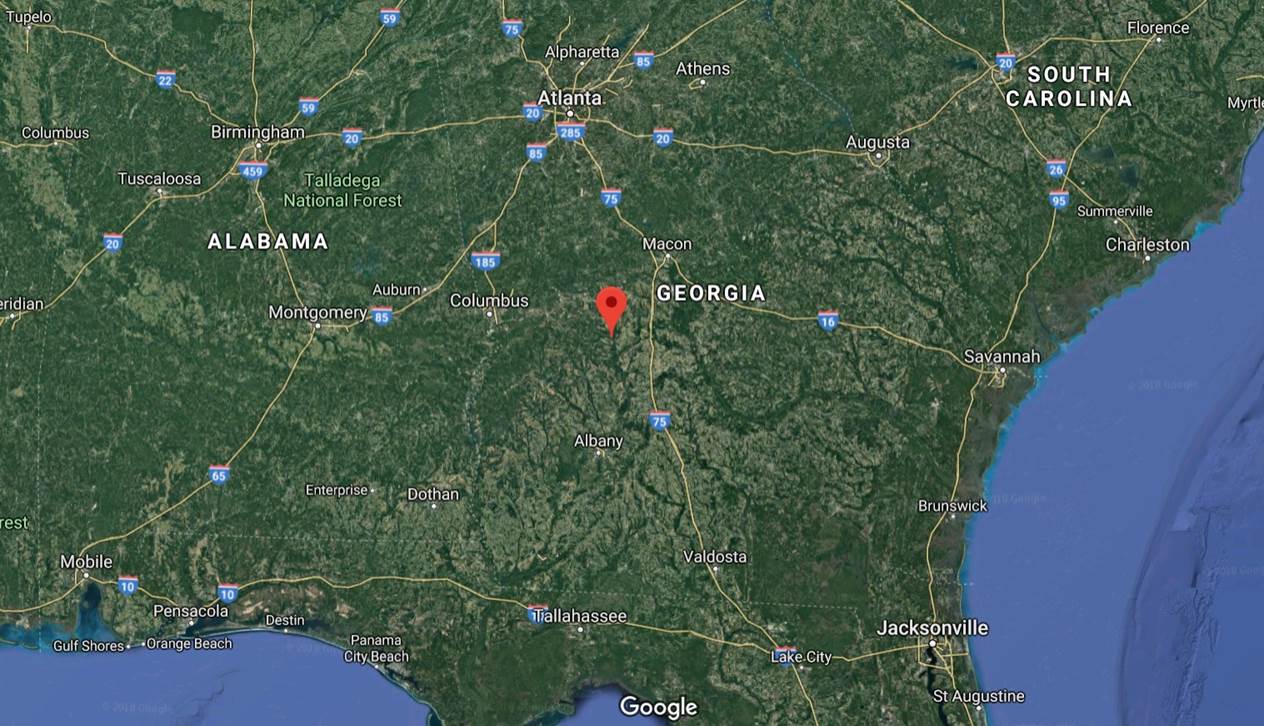

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}16. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Weyerhaeuser Company in Oglethorpe, GA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

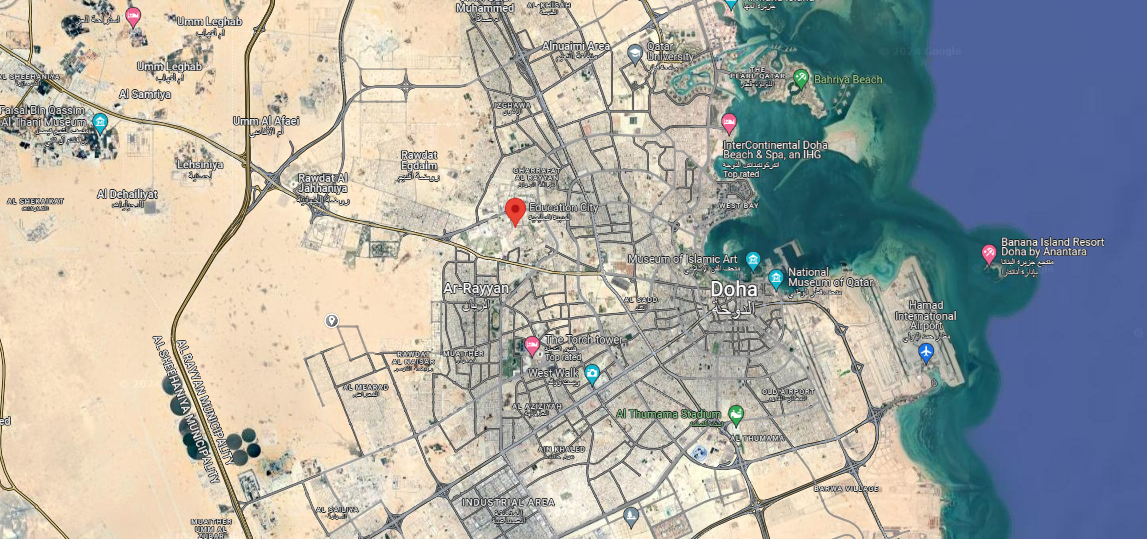

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}17. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Education City in Doha, Qatar |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}18. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Potlatch Mutual Water Company Potlatch, WA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

LUKOIL Kandym project near Karakul, Uzbekistan |

Refineria Batalla de Santa Ines Project in Venezuela |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

World Meridien 101-502 Banghwa-dong Seoul 878-1 Korea {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}19. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Hyundai 41 Tower 917-9 |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||

|

Aerial View |

Side View |

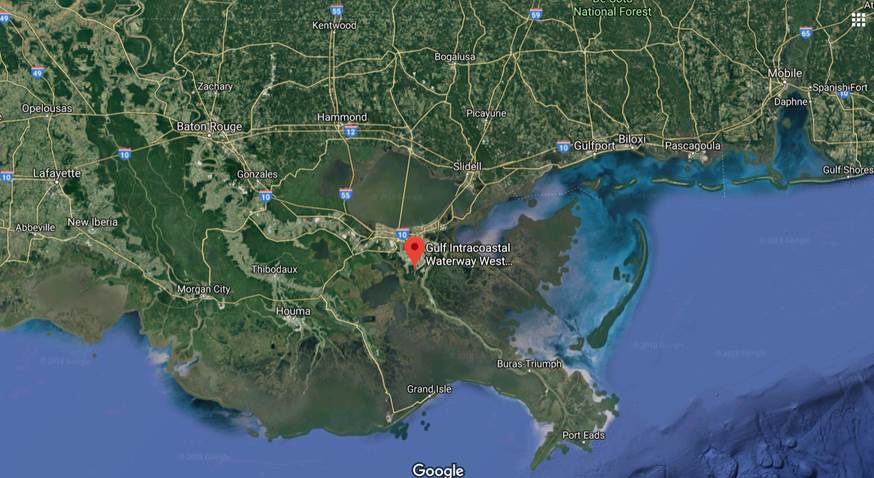

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}20. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}GIWW West Closure (B) 29.815774 N, -90.068493 W |

|

||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||

|

|

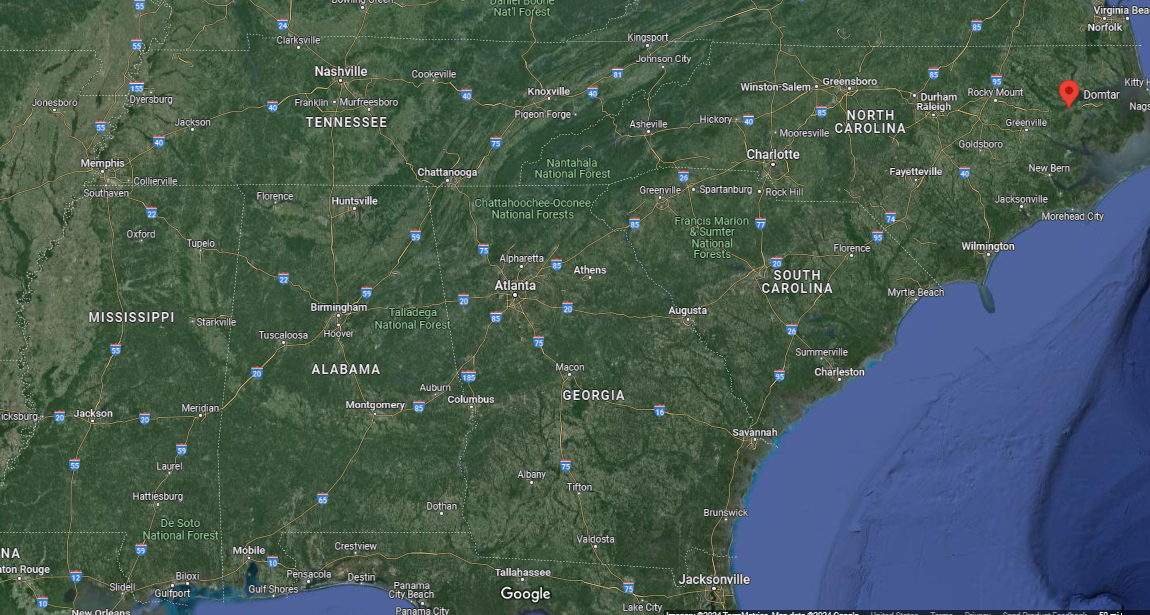

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}21. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}International Paper Franklin, Virginia |

|

|

||||||||||||||||||||||||||||||||||||||

|

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|

||||||||||||||||||||||||||||||||||||||

|

|

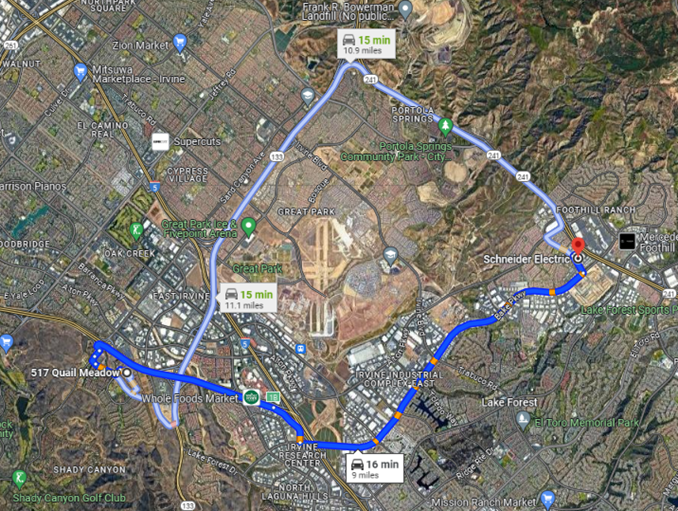

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}22. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Invensys Lake Forest, Californi Diablo Canyon Power Plant |

|

|

||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||

|

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}23. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Energy Solutions Richland, WA |

|

|

||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}24. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Schweitzer Engineering Laboratories, Inc.; Pullman, WA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}25. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Asab Gas Development (AGD 2) LNG Plant Asab, United Arab Emirates |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}26. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Hanford WTP Vitrification Plant Richland, WA |

|

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}27. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Syncrude about 35 km north of Ft Mac Fort McMurray, Alberta Canada |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

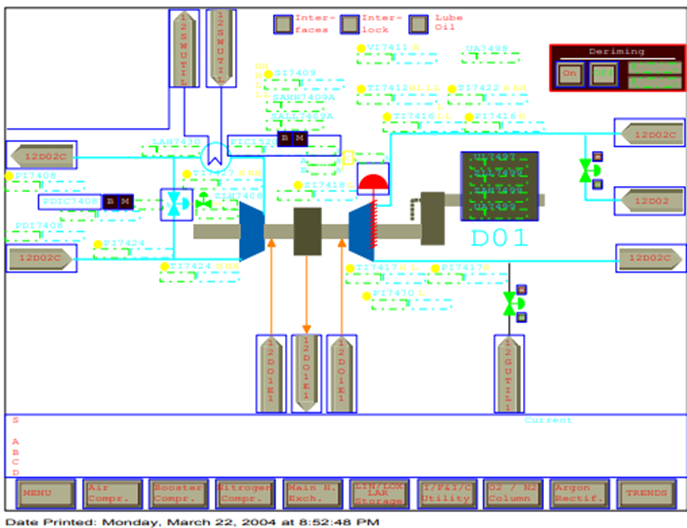

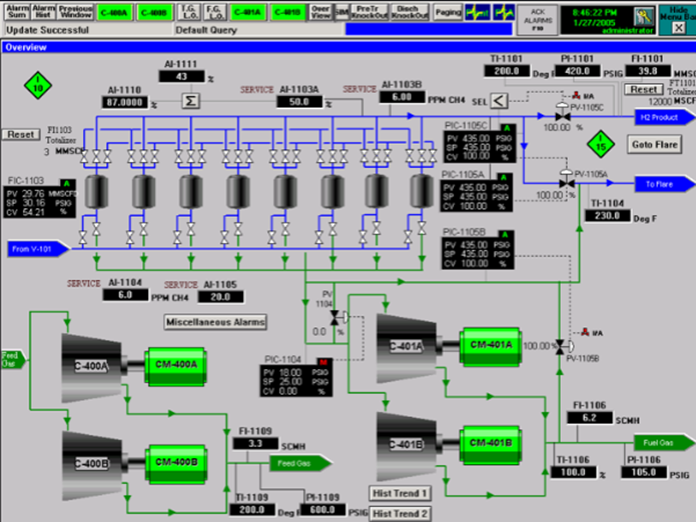

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}28. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Air Liquide Process & Construction; Houston, TX |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

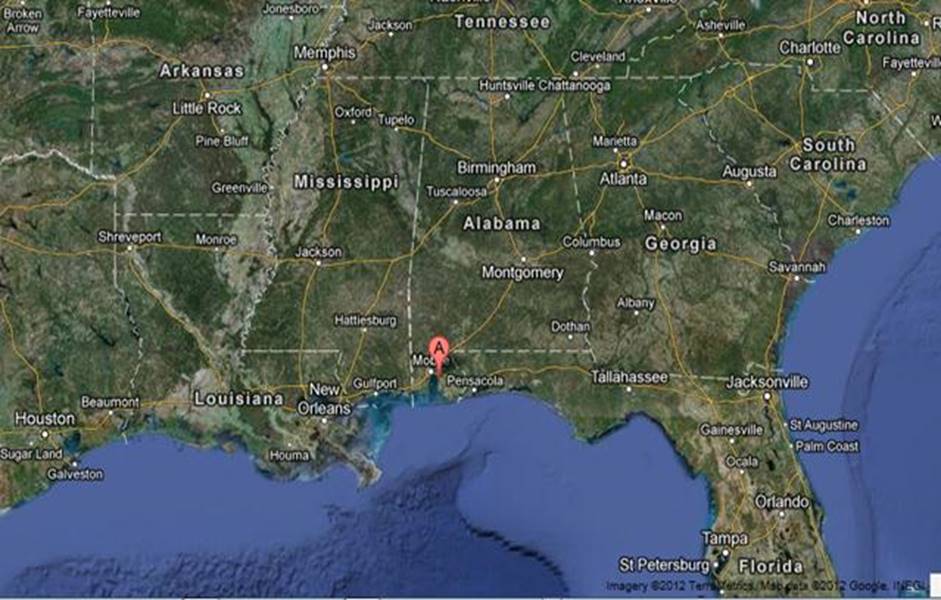

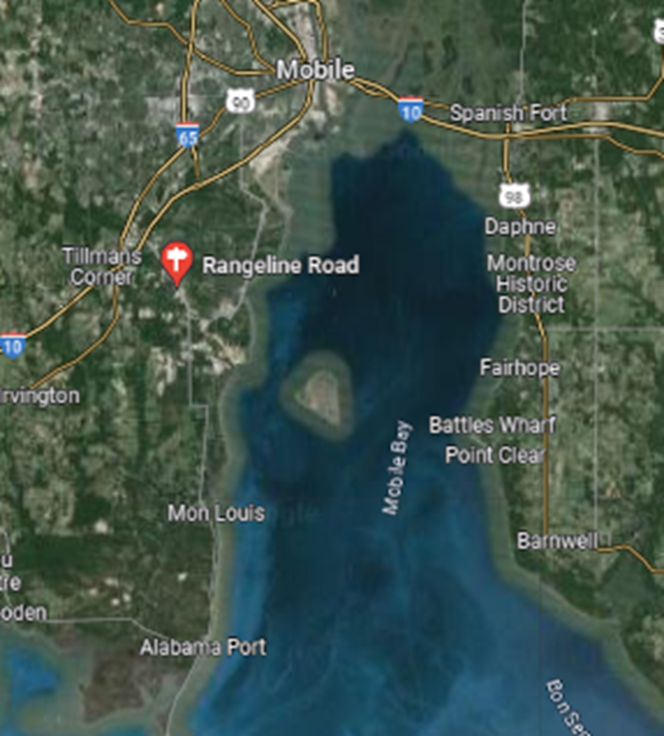

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}29. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}BSC Engineering Daphne, AL on the Eastern Shore of Mobile Bay |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

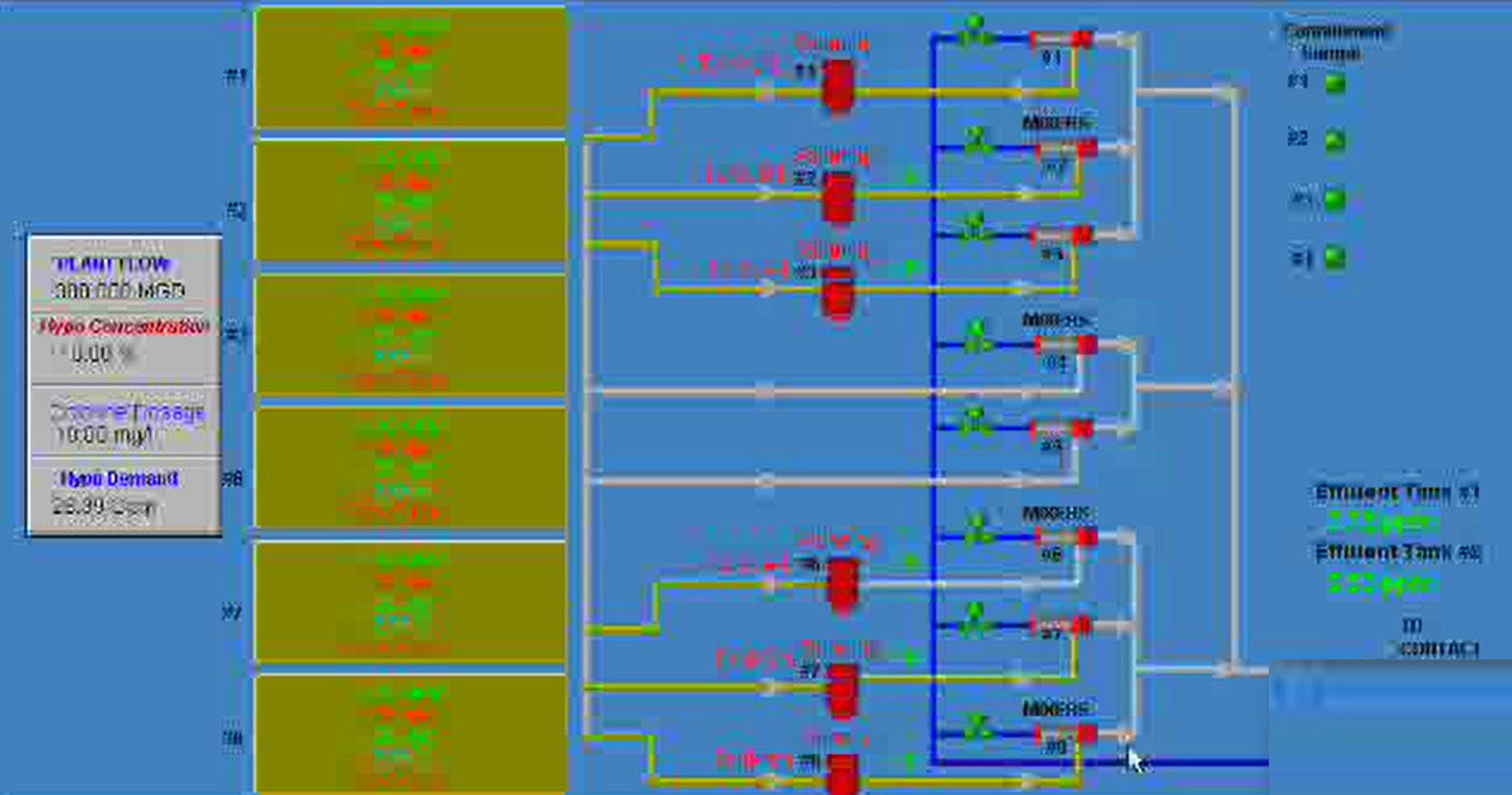

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}30. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}ABB Instrumentation; Warminster, PA for the Northeast Philadelphia Water treatment plant.Water Pollution & Control Project Hypochlorite Modernization |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}31. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}American Electric Power; Houston, TX. Contract Process Control Engineer for the Houston Pipeline/Louisiana Interstate Gas pipelines |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}32. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Process Control Associates, Inc. in Houston, TX. for the Ultramar Diamond Shamrock Three Rivers Refinery Diesel Hydrotreater project |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

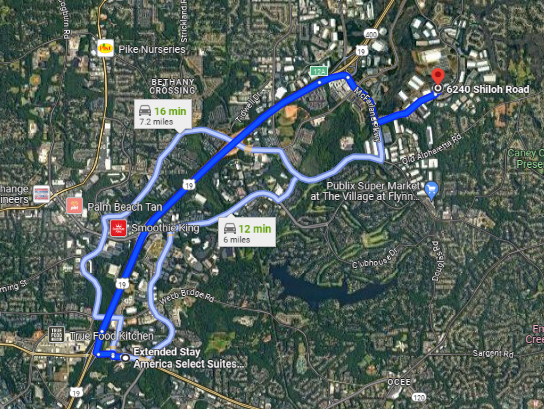

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}33. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Orion CEM, Inc.; Alpharetta, GA. Contract Engineer to Mead Coated Board Inc in Phenix City, AL |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||

|

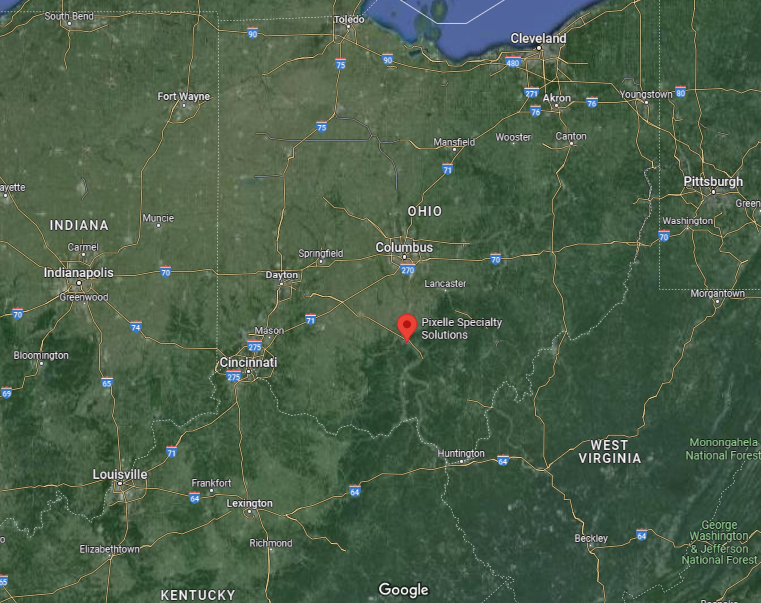

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}34. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}ABB Instrumentation; Columbus, Ohio for the Escambia County Utilities Authority Main Street Wastewater treatment plant Anoxic/Oxic and Secondary Clarifier Project in Pensacola, Florida |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}35. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Ford, Bacon & Davis; Mobile, AL. |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}36. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}GE Industrial Systems; Pensacola, FL |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}37. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Hargrove & Associates in Mobile, AL |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

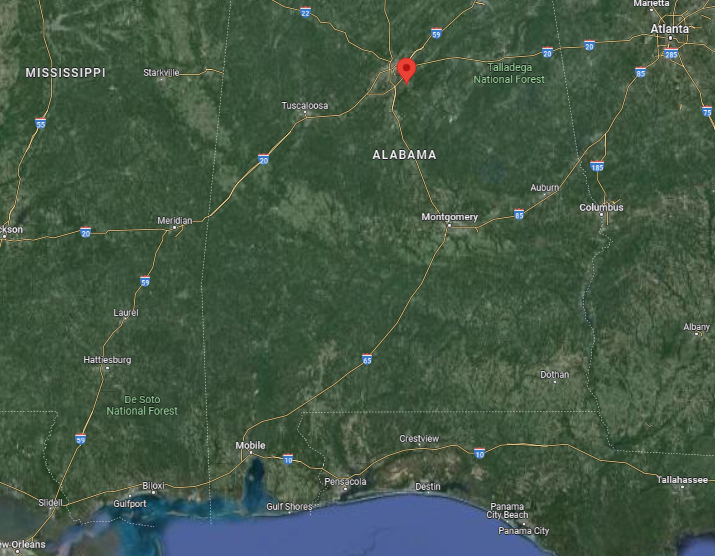

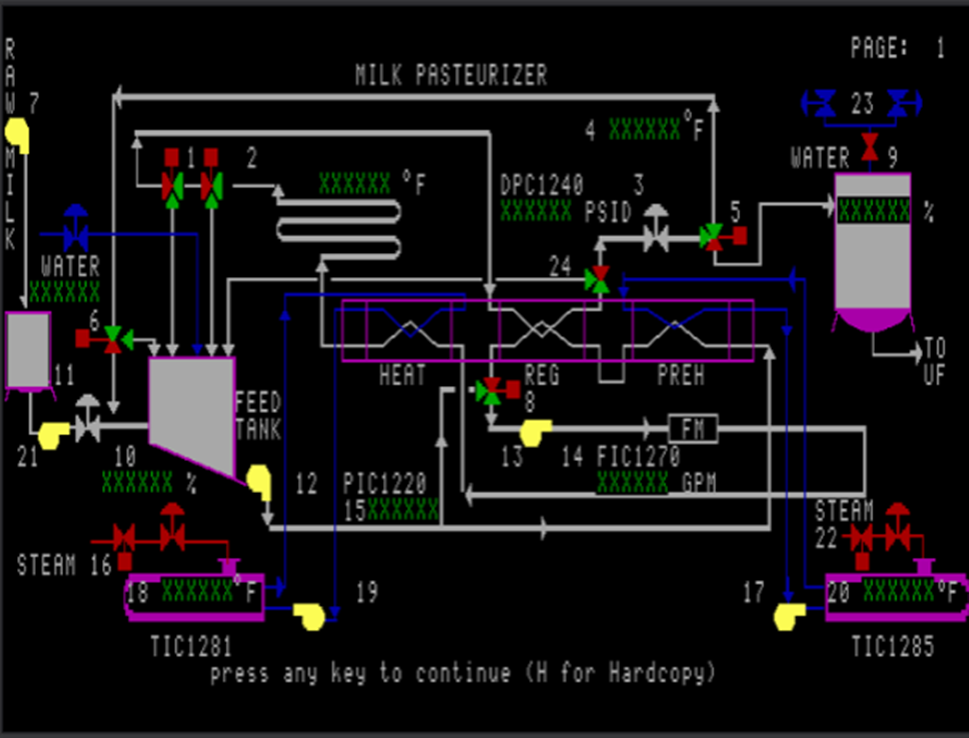

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}38. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Aerotek; Birmingham, AL; Contract Process Control Engineer to Raytheon Engineers & Constructors; Birmingham, AL; for 63 Kraft Foods plants in North America as part of Year 2000 compliance |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

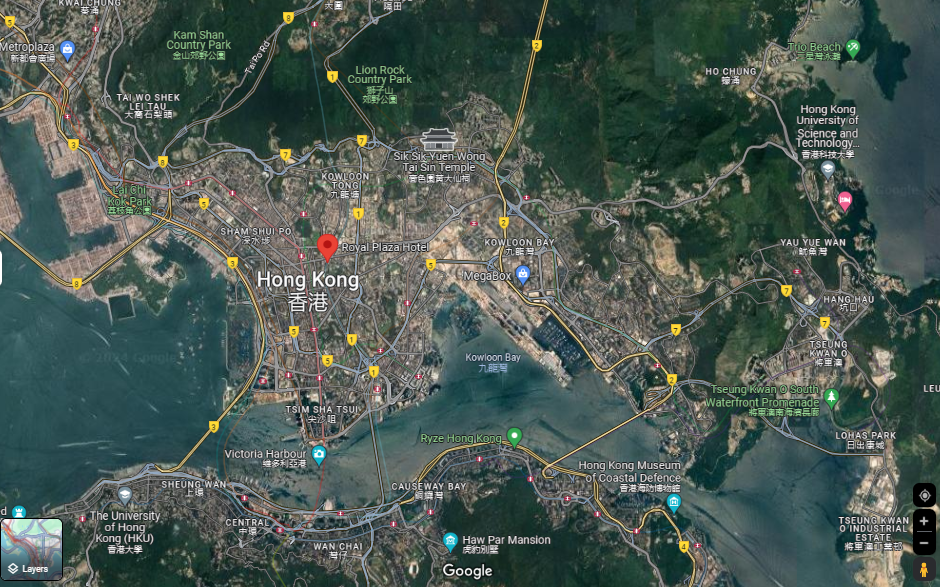

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}39. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Elsag Bailey Process Automation; Wickliffe, Ohio Contract Engineer to Stonecutters Island Sewage Treatment Works Hong Kong Government Strategic Drainage Department |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}40. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Beloit Jacksonville, Florida Indah Kiat Perawang pulp & Paper Mill Sumatra, Indonesia |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}41. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Weyerhaeuser Paper Company; Oglethorpe, GA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

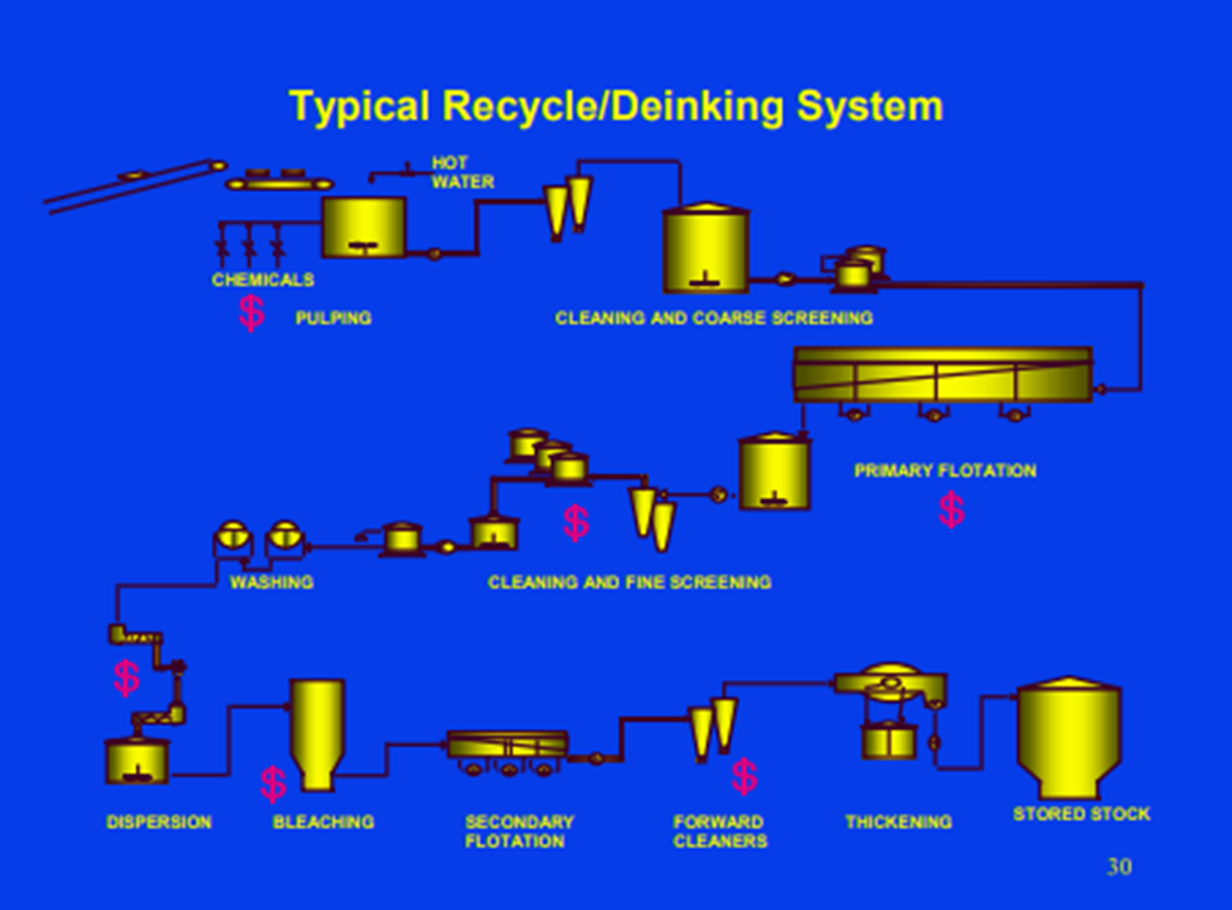

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}42. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Manpower; Phoenix, AZ Contract Engineer to Honeywell Industrial Automation & Controls Division Phoenix, Arizona Wisconsiin Tissue Mills Menasha, Wisconsin (now SCA) |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}43. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}NESC Staffing; Walnut Creek, CA. Contract Engineer to VECO; Bellingham, WA for British Petroleum BP Milne Point, Prudhoe Bay, Alaska |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}44. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Fransen Engineering Ltd. ; Vancouver, BC CANADA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

WESTCOAST ENERGY, INC.; Fort Nelson, British Columbia CANADA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

RAINY RIVER FOREST PRODUCTS, INC.; Fort Frances, Ontario CANADA; |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

RAINY RIVER FOREST PRODUCTS, INC.; Kenora, Ontario CANADA; |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}45. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}BSC Engineering Daphne, AL on the Eastern Shore of Mobile Bay |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Columbus, Nebraska ADM Columbus, NE (Corn Processing |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

BOISE-CASCADE CORPORATION; Emmett, Idaho. |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}46. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}INSTRUMENT CONTROL SERVICES; Pensacola, FL December, 1991 â August, 1993 |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Weyerhaeuser Company; Plymouth, North Carolina |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Mead Paper Company; Chillicothe, Ohio |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

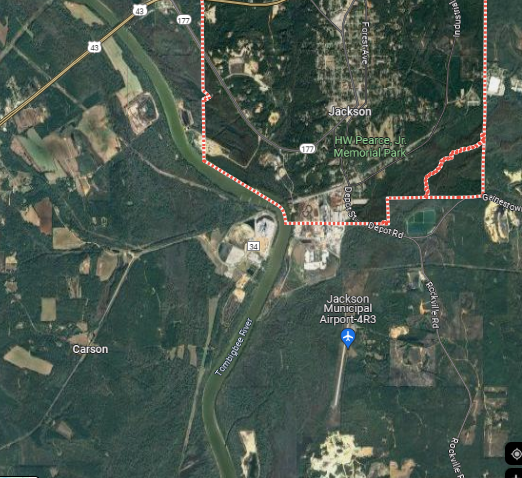

BOISE-CASCADE CORPORATION; Jackson, AL |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}47. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}H.A.Simons Ltd Vancouver, British Columbia Canada |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

BOISE-CASCADE CORPORATION; St.Helens, Oregon. |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

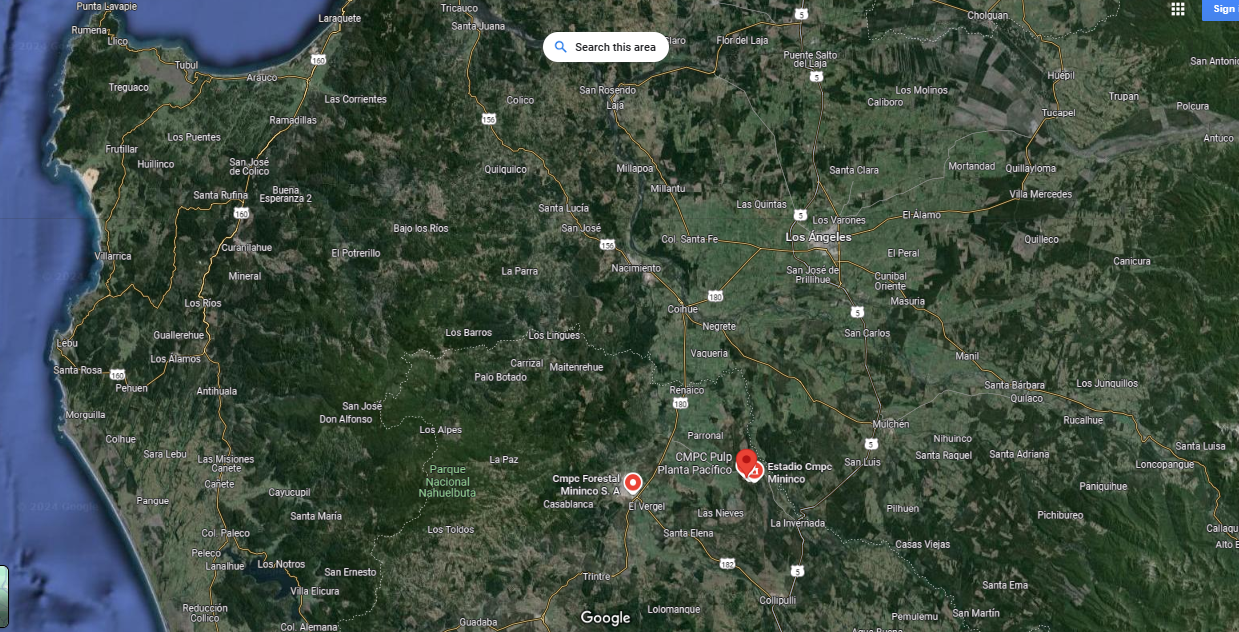

CMPC Pulp Planta Pacífico Mininco, Collipulli, Araucania, Chile |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

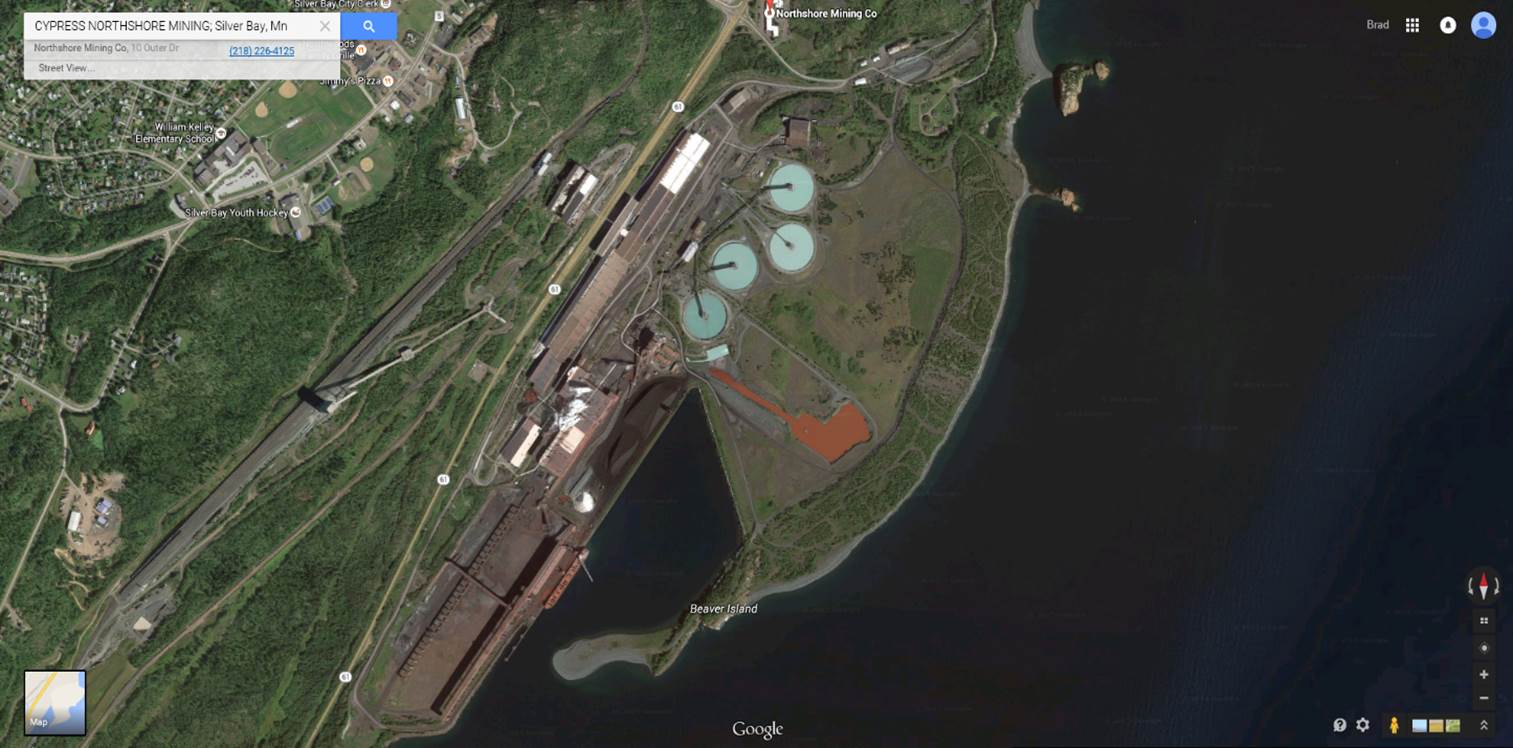

CYPRESS NORTHSHORE MINING; Silver Bay, Minnesota. |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

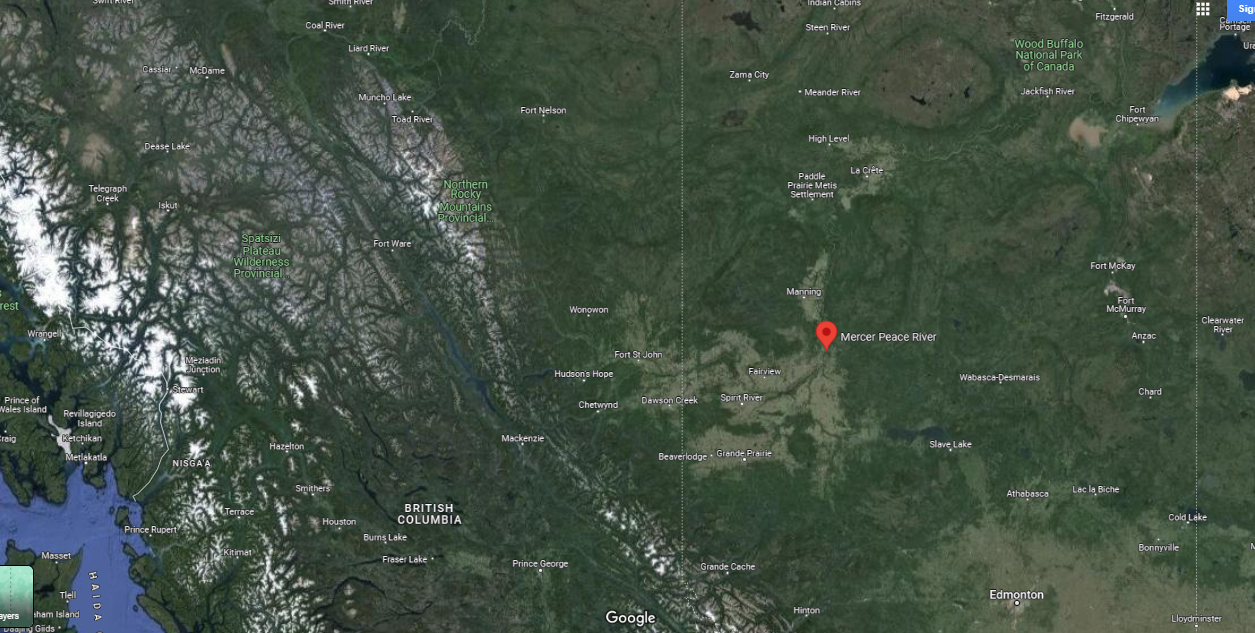

Mercer Peace River, Pulp Mill Site, Peace River, AB Canada |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

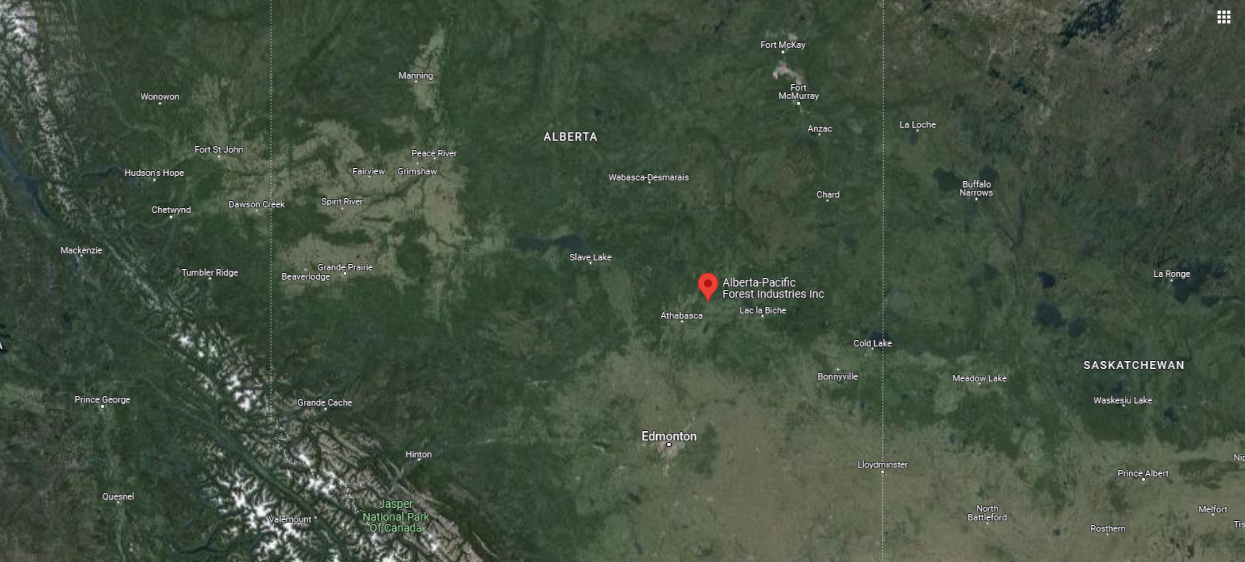

ALBERTA-PACIFIC FOREST INDUSTRIES INC.; Athabasca Boyle, Alberta. |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

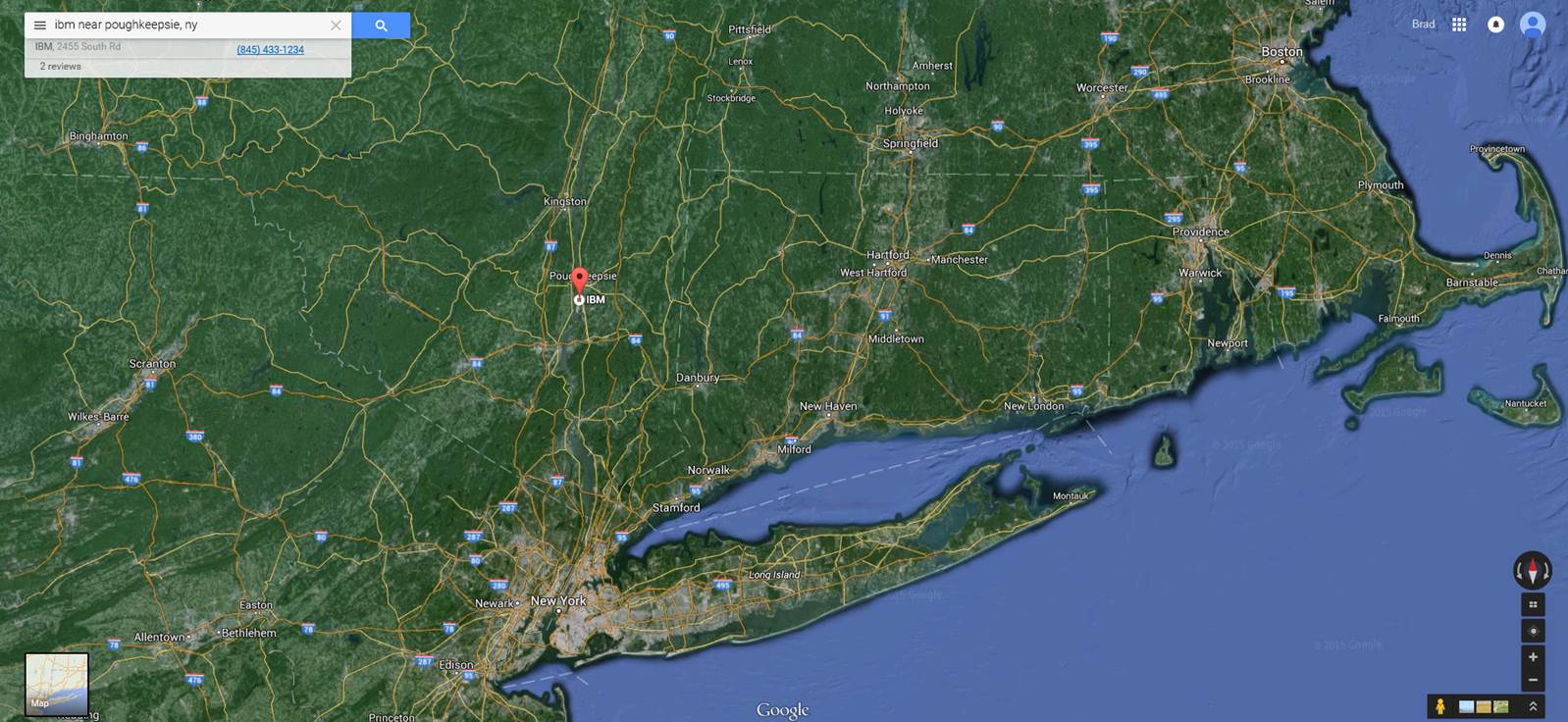

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}48. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}CS Technologies Poughkeepsie, New York & IBM |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Federal Paperboard Sprague, CT |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Potlatch Corporation; Cypress Bend Mill McGehee, Arkansas |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

Interstate Paper Riceboro, Georgia |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

|

Insulating Materials Inc. Schenectady, NY |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}49. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}WRIGHT SCHUCHART HARBOR; Tacoma, WACentral Gas Facility in Kuparek, Alaska |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

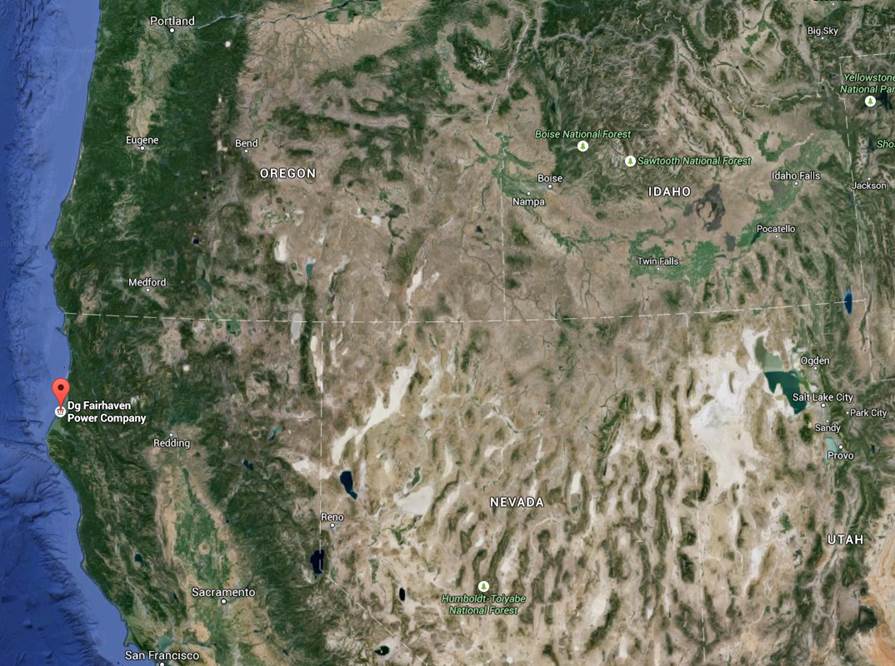

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}50. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}ATLANTIC GULF; Woodinville, WA Fairhaven Power; Samoa, CA |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

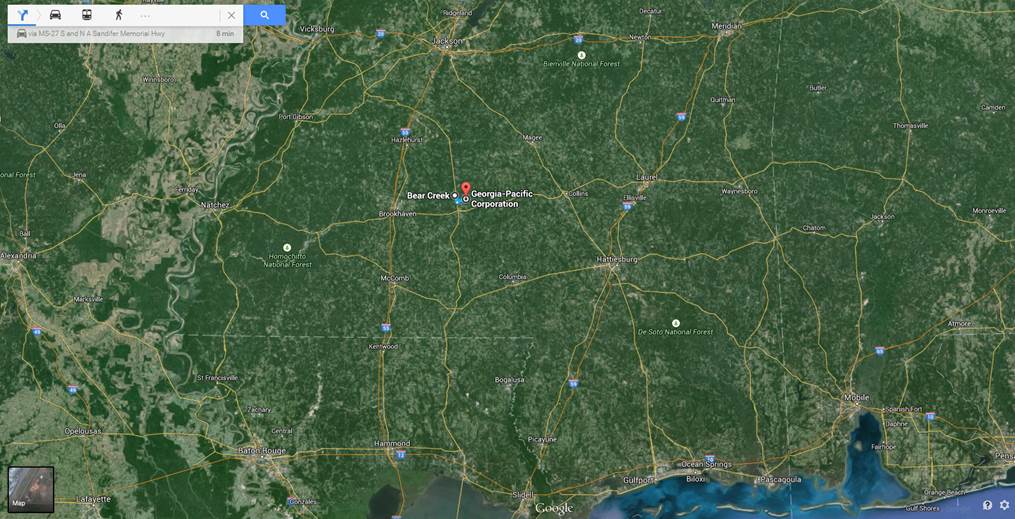

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}51. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}American Technical Services Eugene, OR & Tucker, GA GEORGIA-PACIFIC; Monticello, MS |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}52. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}WEYERHAEUSER COMPANY; Cosmopolis, WA (near Aberdeen) |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}53. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Weyerhaeuser Company Springfield, OR (near Eugene) |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}54. {C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}Weyerhaeuser Company Sawmill Snoqualmie, Washington |

|

||||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|||||||||||||||||||||||||||||||||||||

|

Licensed FAA Single-Engine Land Private Pilot |

3:20 Marathoner |

ASA & CYA Certified Sailor |

51-year Licensed SCUBA Diver |

|

|||||||||||||||||||||||||||||||||||||

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C}{C} |

|

|

|||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Updated January 5, 2025 |

|

||||||||||||||||||||||||||||||||||||||||